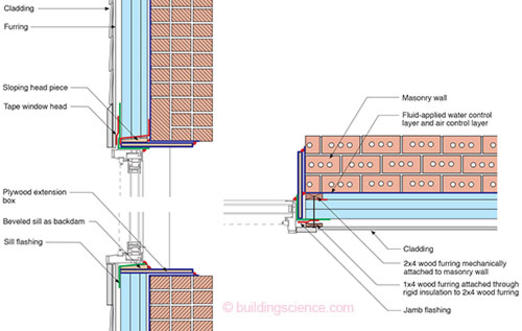

The shorter vertical plane is attached to the upper floor wall under the building paper the lower plane sits on top of the underlayment and under the shingles.

Pto flashing at roof to wall detail.

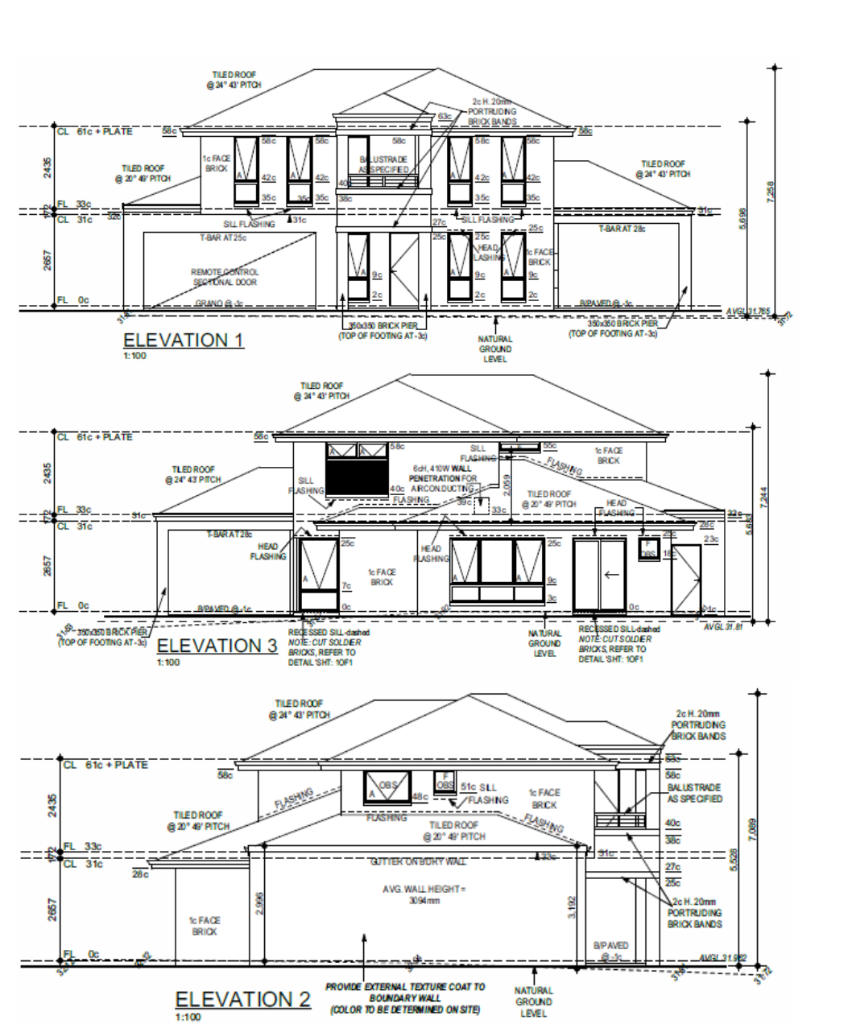

At roof to wall intersections see figure 1.

Pdf t fw m3i tpo self adhered base wall flashing with coping.

The flashing extends up the wall at least 4.

T fw m1 tpo base wall flashing with coping master detail.

Paraguard expansion joint roof to roof with parasolo flashing.

Flashing joints are lapped 6 in the direction of water flow.

Tape the top of step flashing with 4 inch wide minimum self adhering modified bitumen roof tape.

Paraguard expansion joint roof to wall with parasolo flashing.

Pdf t fw m2i highwall flashing with metal backing strip isometric view master detail.

The detail drawings are grouped by details and can be downloaded below in dwg or pdf format.

The flashing extends onto the roof a minimum of 2 inches 4 inches is preferable in more severe climate areas.

Turn the roof underlay up under adjacent wall underlay 1a and overlap the lower wall underlay 1b.

Roof area divider curb type.

Roof to wall flashing is bent at a 110.

Step flashing protects the gap where roofs meet walls by weaving into the roof shingles.

Finally the housewrap can be laid up on the wall to cover the top of the kickout diverter and step flashings.

It is designed to cover and protect roof to wall intersections from water infiltration.

Cut and fold a section of the membrane across the roof underlay turn down.

Pdf t fw m1i tpo base wall flashing with coping isometric view master detail.

Because most roof flashing is required to extend up the wall a minimum of 4 and some a minimum of 5.

High wall flashing detail 5 wide sheets.

Figure 2 steps 1 2 roof wall junction construction sequence.

The roof flashing is then placed up behind this through the wall z bar flashing on the outside of the vertical blocking backing material.

At the bottom of the roof water needs to be directed.

Fit a self adhesive flexible flashing membrane over the junction.

Hold your cursor over the file name to view when a drawing was last updated.

High wall flashing detail 10 wide sheets.

The narrower step flashing just isn t wide enough to protect the intersection fully.

Firestone has developed cad drawings of its tpo installation details to assist roofing professionals with the specification of firestone tpo roofing systems.

Rain should run off the roof and into the gutter.

Do not seal housewrap or building paper to step flashing.

Wall base termination detail.

I recommend 12 in wide step flashings bent for a 5 in.

The metal flashing is formed with a hook edge and cleated on 12 centers.

Roof leg and a 7 in.

Use step flashing that has a 2 to 4 inch longer vertical leg than normal.

Wall flashing with coated metal edge.