Safplate s unique combination of pultruded fiberglass plate and an anti skid grit surface creates textured solid sheet flooring that is ideal for both wet and dry environments.

Pultruded fiberglass sheet piling.

Round octagonal pipes general diameters are from 8 to 14 the length can be 4ft 20ft even 30ft.

Were part of venice s mose system aimed at the protection of the city and its high water lagoon.

Pultruded fiberglass sheet piling pultruded sheet piling is a section of piling that is manufactured by the continuous processing of raw materials by pulling resin rich reinforcements through a heated steel die to form profiles of constant cross section of continuous length.

It has 2 primary characteristics.

As an frp pultrusion manufacturer our high strength pultruded fiberglass products are designed and manufactured to provide lasting performance in highly corrosive environments while offering lightweight and high dielectric strength benefits as compared to traditional materials of construction.

Frp sheet piling is a cutting edge building product that offers many advantages over traditional materials such as steel.

Pultruded fiberglass flat sheets come in various thicknesses and dimensions.

Pultruded fiberglass flat sheets come in several sizes ranging from 24 x 1 8 to 48 x 1 liberty pultrusions is a leading manufacturer of high quality durable lightweight structural frp flat sheets which are used in many types of applications.

Pultruded sheet piling is manufactured from a process utilizing high performance space age composites.

Fiberglass gritted plate is a tough corrosion resistant floor plate.

Fiberglass sheet piles produced by saimex s r l.

Fiberglass composite piles include round octagonal pipes and sheet piles.

This choice was dictated by the fact that our products made with innovative materials guarantee long durability in contact with water.

Traditional pile materials are steel and aluminum.

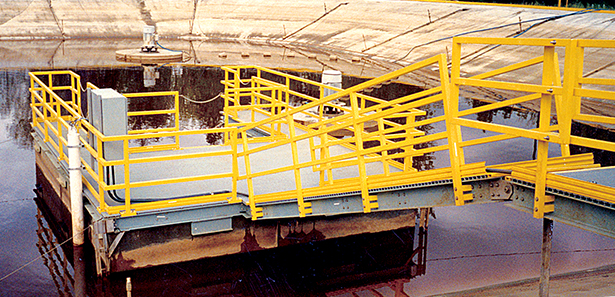

Superloc all composite sheet pile system is a patented fiberglass sheet pile retaining wall structure for waterfront applications where environmental considerations require a sheet pile wall structure that will not rot decay rust or spall.

It is manufactured incorporating continuous fiber reinforced roving and matting combined with a high strength resin.

.jpg)